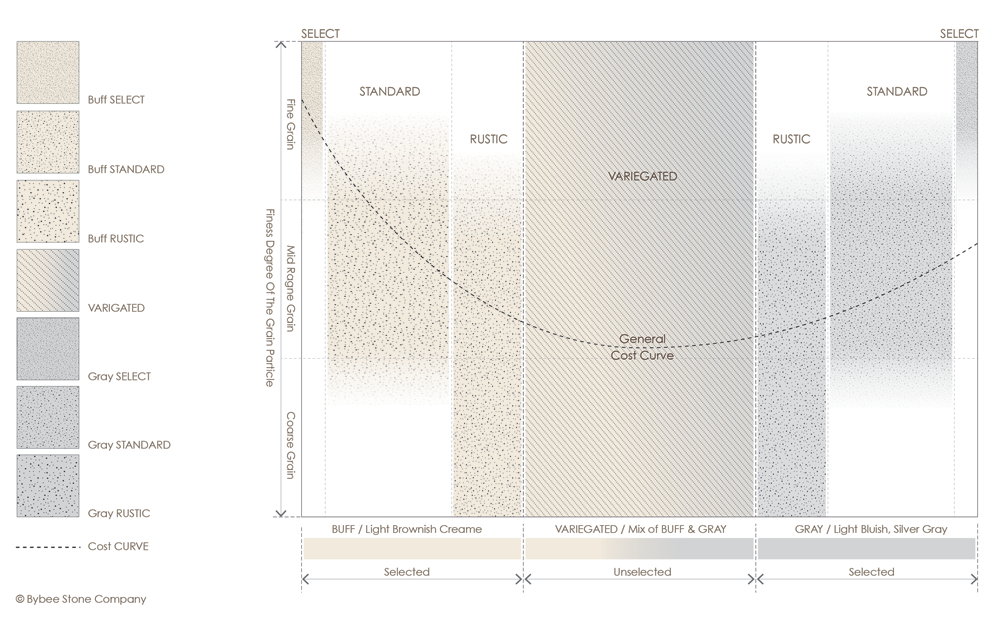

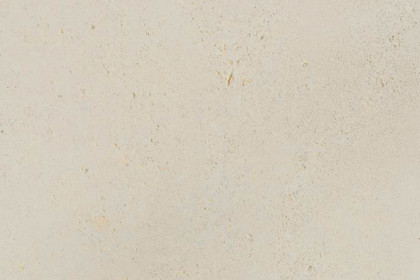

Indiana limestone comes in an elegant range of shades – from silver blue to rich, creamy tan – and textures, ranging from consistently smooth to a rustic blend of assorted grain and fossil sizes. While Bybee Stone Company follows the classification guidelines of the Indiana Limestone Institute, Indiana limestone is a natural material that can range either subtly or substantially from one shade to another within any given sample.

When it comes to finishes, Bybee Stone Company is capable of providing any finish your project may require. If your design needs a particular textural finish, talk to us, and we’ll make the tools to get the finish right. Our finishes include, but are not limited to: plucked, tooled, bushhammer, crandle, 9-point, rock face, split face, plow, chatsawn, and shotsawn.

For further information on the physical and structural characteristics of Indiana limestone, please visit the Indiana Geological Survey’s page on Indiana limestone.

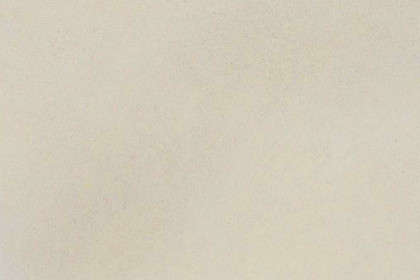

Buff Smooth

Featured Projects:

Iowa State Capitol

Millennium Park

Schermerhorn Symphony Center

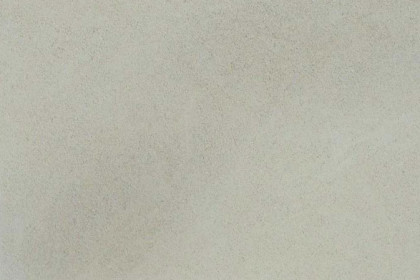

Gray Smooth

Featured Project Page:

Seattle Art Museum

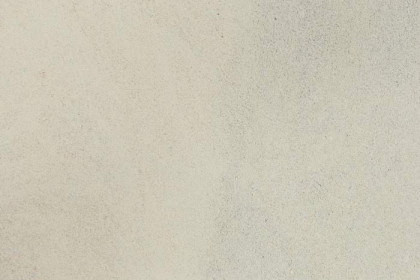

Variegated Smooth

Variegated Indiana limestone is in no way a lower quality than buff or gray. Its lower relative cost stems from lower labor costs – there is no need to separate out specific colors or grades of stone. Many high profile projects have utilized Variegated Indiana limestone to great effect, including the Pentagon, Reagan Building and Federal Triangle, all in Washington, D.C.

Rustic Buff

Featured Projects:

Duke Divinity School

Whitman College

Chatsawn

Shotsawn