Bybee Stone Tools is proud to offer many services throughout the fabrication process, from the moment quarries break ground to the finished product you see on buildings. Starting at the quarry, we provide bottom line bits, slips and wedges, bull wedges and slips. Once the stone enters the mill in block form, we machine gang-feed screws and nuts that control the cutting process. We service gang carts and saw beds, as well as many other unique parts, even those that have become scarce over time.

In slab form, the stone goes to the planers, where we provide the tools for cutting the profile. We also provide machined parts for the planers including planer wedges, feed screws, planer dogs, and repaired tool stocks. We supply planer hammers to “dog” the stone down to ensure that stone remains in place throughout the planing process. We manufacture custom dog picks and planer hammers. Do you have a dog pick, but no dogs? No problem. We can make new, custom dogs and have them sent for approval for the desired weight certification.

After the stone is planed, it is then jointed and sawn to size. To assist in this process, we can make new rollers, or service old rollers to help get the stone on to the sawing beds. Once transitioned to the stone-cutting process, our hand-carving tools are utilized to complete a custom finish. These tools can take on any shape or size, to the exact specifications of the customer. Likewise, for rock-face or split-face finishes, we hammer out pitching tools to “pitch” the smooth face off the stone to achieve the distinctive texture.

HISTORY

Bybee Stone Tools began in 1989 when Wilbur Bybee bought an existing business, Moore’s Welding. Dan Roberts, who had 10 years of machine shop experience, had been training with Vestal Barger, Bybee Stone Company’s blacksmith, and became manager of the new tool shop.

Roberts has produced tools for nearly every major stone mill in the country. Today, every piece of equipment purchased in 1989 has been replaced to better serve production.

TOOL CUSTOMIZATION

Roberts receives a customer’s specifications—drawings or patterns—and hand fabricates each tool using steel shanks and carbide for the cutting edges. He insists that there’s nothing standard when it comes to profiles in the stone business—that it’s always something different. “People who really know the business,” Roberts said, “and want a good tool, a good finished product, they come to us.”

STANDARD HAND CARVING TOOLS

Roughing out hand tools:

- round nose tooth, varying widths

- point, various sizes

Roughing Out Specifications (PDF)

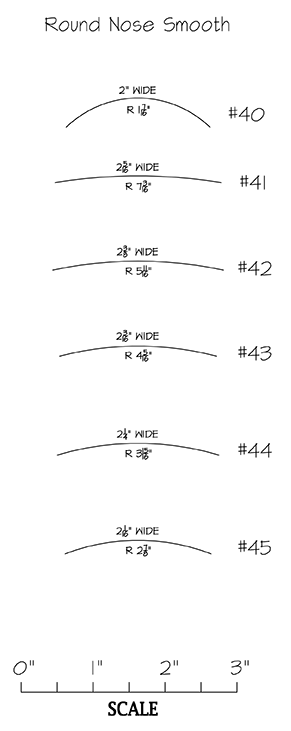

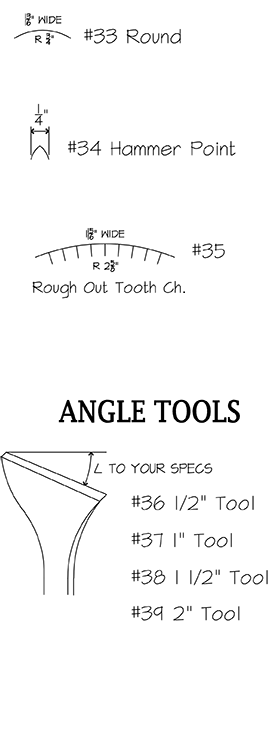

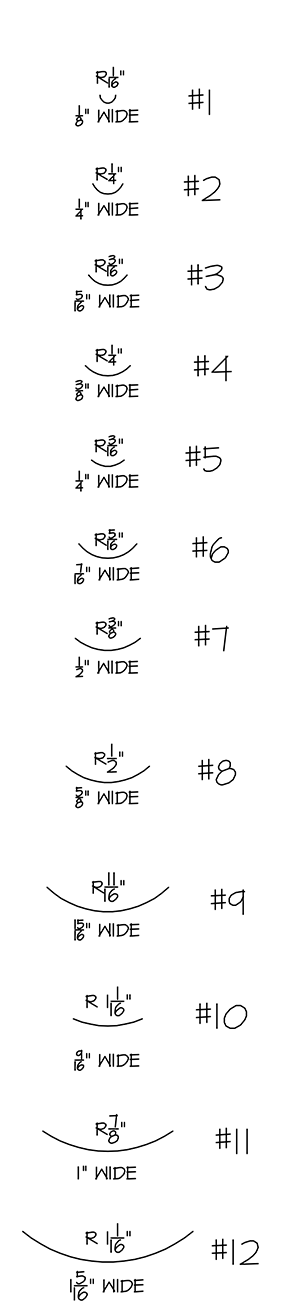

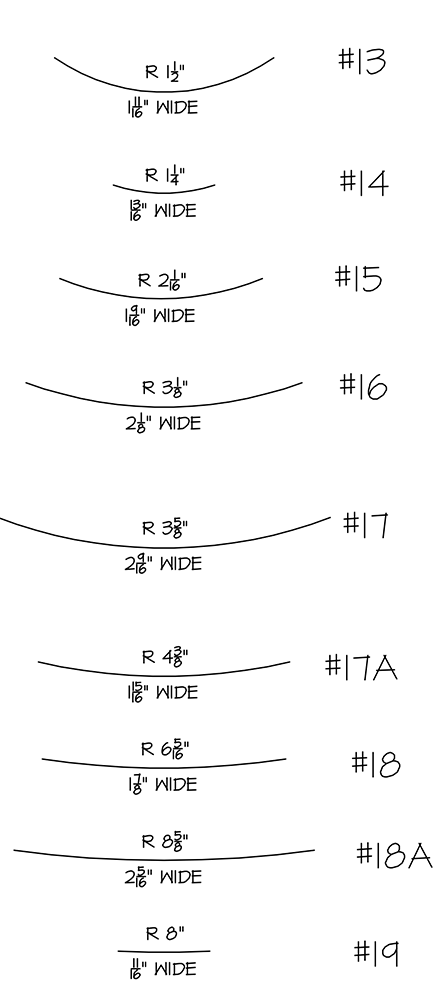

Gouges, various sizes, all with radius:

- with teeth, roughing out

- without teeth, finish work

Flats, various sizes:

- with teeth, roughing out

- without teeth, finish work

A hand carving starter set can vary, but often includes:

- ¼” point

- 1” round-nose rough-out tool

- 1” flat, smooth

- 1” smooth gouge

Click through to the following to select

radius and size for your gouge.

Tool Angles

Gouges

Location: 6525 W. Maple Grove Rd. Ellettsville, IN 47429

Mailing: PO Box 308, Ellettsville, IN 47429

Phone: (812) 876-3058

Fax: (812) 935-6180

Email: tools@bybeestone.com